This product is not available for new orders. We recommend ordering: CR1000Xe.

| Services Available |

|---|

Resumen

El CR1000X es nuestro datalogger buque insignia de propósito general, diseñado para ser utilizado en una amplia variedad de aplicaciones en medida y control. El CR1000X es lo suficientemente robusto para uso en condiciones extremas, con una fiabilidad que lo convierte en una excelente opción para aplicaciones medioambientales remotas, como estaciones meteorológicas, sistemas mesonet, perfiles de viento, monitorización calidad del aire, sistemas hidrológicos, monitorización calidad del agua y estaciones hidrometeorológicas.

El CR1000X es un dispositivo de muy bajo consumo, que mide las señales de sensores, controla las telecomunicaciones, analiza los datos, controla dispositivos externos y almacena datos y programas en su propia memoria no volátil. La electrónica está protegida contra la radiofreceuencia mediante una exclusiva carcasa sellada de acero inoxidable. El reloj interno se mantiene con una pila de respaldo. Se programa mediante el lenguaje de alto nivel CRBasic, igual que todos nuestros dataloggers, y que permite implementar rutinas para procesado y análisis de los datos.

Leer másVentajas y características

- Funcionamiento en condiciones extremas, rango estándar de -40°C a +70°C , y extendido opcional de -55°C a +85° C

- Conexión directa a puerto USB ordenador

- Alta velocidad de muestreo de señales analógicas de hasta más de 300Hz

- Alta resolución en las medidas analógicas de voltaje mediante conversor A/D de 24 bit

- Incluye dos canales de medida exclusivos para señales 0-20 mA o 4-20 mA

- Puerto CPI para conexión de módulos distribuidos CDM de Campbell Scientific

- Toma Ethernet RJ45

- Ranura para tarjeta microSD para ampliación de memoria

- Comunicaciones serie con dispositivos y sensores mediante SDI-12, RS-232, y/o RS-485

- Soporta enrutamiento PakBus

- Página web embedida

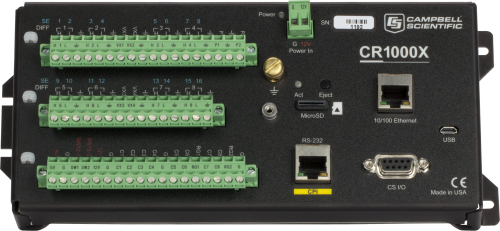

Imágenes

Ficheros CAD:

Descripción detallada

El CR1000X es un dispositivo electrónico de bajo consumo diseñado para medir señales de sensores, gestionar conexiones directas y por telecomunicaciones, analizar datos, controlar dispositivos externos, y con almacenamiento interno no volátil para guardar datos y programas. La electrónica queda protegida de interferencias RF y fallos dentro de un cartucho sellado en acero inoxidable. El reloj está salvaguardado con una pila de respaldo interna. El lenguaje de programación CRBASIC -común a todos los dataloggers Campbell Scientific- permite programar el procesado y análisis de datos.

El panel de conexiones del CR1000X incluye dos terminales de salida 12 V configurables por software, terminales de tierra distribuidos por los 16 terminales analógicos y bloques de terminales removibles.

Preguntas frecuentes

Número de FAQs relacionadas con CR1000X: 8

Expandir todoDesplegar todo

-

The CPI bus speed is adjustable in your CRBasic data logger program. Use the CPISpeed() instruction in your CRBasic program to adjust the CPI bus bandwidth to meet the following maximum combined (total) Ethernet cable lengths:

- 1000 kB/s for maximum combined Ethernet cable lengths of 15.2 m (50.0 ft)

- 500 kB/s for maximum combined Ethernet cable lengths of 61 m (200 ft)

- 250 kB/s for maximum combined Ethernet cable lengths of 152.4 m (500 ft)

-

The potential transformer and the current transformer provide differential outputs that have galvanic isolation from the voltage and current in the circuit they are measuring. However, there is no need to run the outputs of these transformers into differential inputs of the data logger and unnecessarily consume additional data logger channels. We conducted extensive testing for noise immunity, for inaccuracies from ground loops, and more before concluding that single-ended measurements in the ACPower() instruction have the same performance as differential measurements would provide. Please note that as a result of the galvanic isolation of the potential transformer and current transformer, the data logger ground is NOT connected to the ground of the circuit they are measuring.

Said differently, you can connect differential outputs of a sensor to single-ended inputs of the data logger. However, doing so creates the possibility of poor common-mode noise rejection in the data logger and the possibility of introducing inaccuracies from ground loops between the sensor and the data logger. Note that in this application, the transformer isolation of the potential transformer and the current transformer eliminates these concerns.

Simply connect one of the potential transformer secondary wires and one of the current transformer secondary wires to the data logger ground. Which wire in either case makes a difference, as the phase information allows the measurement of power flowing in either direction. If you measure negative real power when it should be positive, then reverse the secondary wires of the potential transformer where they connect to the data logger. Alternatively, you can reverse the secondary wires on the current transformer, but don't reverse both pairs of wires.

-

Return the CR1000X to Campbell Scientific for repair. For assistance obtaining a Return Material Authorization (RMA), follow the instructions on the Repair and Calibration page.

-

The CR1000 and CR1000X will be sold concurrently for no less than two years. We anticipate the CR1000 will be retired in December of 2019 and will be supported until December of 2029.

-

When idle, the CR1000, CR6, and CR1000X consume less than 1 mA @ 12Vdc. Similar to the CR6, the CR1000X has a much faster processor that requires more power when up and running. As such, there will be higher current draws during active measurements, serial communications, or when plugged into a PC via USB or Ethernet.

It may be helpful to think of the CR6 and CR1000X as being built on the same "platform."

-

Although there are significant additions to the CR1000X program instructions that are not available in the CR1000, in most cases, you can load your program written for the CR1000 to a CR1000X with minor instruction changes. The most notable of the minor instruction changes is in the analog measurement instructions. For more information, see the "Replacing Your CR1000 Data Logger with a CR1000X: What You Should Know" blog article.

Compatibilidad

Nota: lo siguiente muestra información de compatibilidad notable. No es una lista de todos los productos compatibles.

Medida y Control

| Producto | Compatible | Nota |

|---|---|---|

| SDM-SIO2R |

Software

| Producto | Compatible | Nota |

|---|---|---|

| DevConfig | Version 2.16 or higher | |

| LNLINUX | Version 4.5 or higher | |

| LoggerLink | Version 1.6 or higher | |

| LoggerNet | Version 4.5 or higher | |

| PC200 (retired) | Version 4.5 or higher | |

| PC400 | Version 4.5 or higher | |

| RTDAQ | Version 1.3 or higher | |

| Short Cut | Version 4.0 or higher |

Miscelaneo

| Producto | Compatible | Nota |

|---|---|---|

| KonectGDS |

Información de compatibilidad adicional

Sensores

El CR1000X dispone de diversos tipos de canales de entrada, y es compatible con casi todos los sensores disponibles en el mercado, incluyendo analógicos (voltaje y corriente), termopares, serie RS232/RS485, SDI-12, pulsos y frecuencia.

Periféricos de medida y control

El CR1000X es compatible con todos nuestros módulos CDM, SDM, multiplexores, interface de cuerda vibrante, TIMs y relés.

Comunicaciones

El CR1000X puede comunicarse con un PC por conexión directa por USB, EtherNet 10/100baseT, Wi-Fi NL241, modems multidrop (RS485), modems telefónicos (línea terrestre u línea móvil), radio y satélite (Argos, GOES, Meteosat, Iridium, Inmarsat).

Los datos pueden visualizarse in-situ también mediante los teclado/display CR1000KD, CD100, CD295, móvil/tableta con iOs o Android (y software LoggerLink), o con otros dispositivos de terceros.

Armarios intemperie

El CR1000X con una fuente de alimentación se ensamblan habitualmente dentro de uno de nuestros armarios.

Alimentación eléctrica

Cualquier fuente de 12Vdc puede alimentar el datalogger CR1000X. Habitualmente se usan nuestras fuentes BPALK, PS150 y PS200.

Software

Para programar, configurar y comunicar con el datalogger CR1000X, es necesario nuestro software Campbell Scientific. Hay disponibles diversas opciones software en función de los requerimientos de cada aplicación. Los más básicos y gratuitos son el Short Cut y PC200W. Consúltenos y le indicaremos que software es el más adecuado para su aplicación.

Especificaciones

| -NOTE- | Additional specifications are listed in the CR1000X Specifications Sheet. |

| Operating Temperature Range |

|

| Maximum Scan Rate | 1000 Hz |

| Case Material | Anodized aluminum |

| Analog Inputs | 16 single-ended or 8 differential (individually configured). Two analog inputs can measure 4 to 20 mA or 0 to 20 mA natively. Four analog inputs can provide pulse/digital I/O functions. |

| Pulse Counters | 10 (P1 to P2 and C1 to C8) |

| Voltage Excitation Terminals | 4 (VX1 to VX4) |

| Maximum Source/Sink Current |

|

| Communications Ports |

|

| Data Storage Ports | microSD |

| Switched 12 Volt | 2 terminals |

| Digital I/O | 8 terminals (C1 to C8) configurable for digital input and output. Includes status high/low, pulse width modulation, external interrupt, edge timing, switch closure pulse counting, high-frequency pulse counting, UART, RS-232, RS-485, SDM, SDI-12, I2C, and SPI function. Terminals are configurable in pairs for 5 V or 3.3 V logic for some functions. |

| Input Limits | ±5 V |

| Analog Voltage Accuracy |

|

| ADC | 24-bit |

| Power Requirements | 10 to 18 Vdc input (See manual for further details.) |

| Real-Time Clock Accuracy | ±3 min. per year (Optional GPS correction to ±10 µs) |

| Internet Protocols | Ethernet, PPP, RNDIS, ICMP/Ping, Auto-IP (APIPA), IPv4, IPv6, UDP, TCP, TLS (v1.2), DNS, DHCP, SLAAC, Telnet, HTTP(S), SFTP, FTP(S), POP3/TLS, NTP, SMTP/TLS, SNMPv3, CS I/O IP, MQTT |

| Communications Protocols | CPI, PakBus, SDM, SDI-12, Modbus, TCP, DNP3, UDP, NTCIP, NMEA 0183, I2C, SPI, and others |

| Battery-backed SRAM for CPU Usage & Final Storage | 4 MB |

| Data Storage | 4 MB SRAM + 72 MB flash (Storage expansion of up to 16 GB with removable microSD flash memory card.) |

| Idle Current Drain, Average | < 1 mA (@ 12 Vdc) |

| Active Current Drain, Average |

|

| Dimensions |

23.8 x 10.1 x 6.2 cm (9.4 x 4.0 x 2.4 in.) Additional clearance required for cables and leads. |

| Weight | 0.86 kg (1.9 lb) |

Documentos

Folletos producto

Manuales

Documentos técnicos

Videos & Tutoriales

Descargas

CR1000X(e) OS v.8.2.1 (6.71 MB) 07-04-2025

This download is for the CR1000X and CR1000Xe dataloggers. Execution of this download places the Operating System file(.obj) on your computer. It also updates the CRBasic Editor compiler and support files.

Why Update? New features and bug fixes. With this OS update it is recommended that you also update the Device Configuration Utility to the most recent version so that new datalogger features are available in the utility.

Note/Warning: Campbell Scientific always recommends updating operating systems on site if possible. When remote updates are required, it is recommended that you implement the necessary precautions to handle unexpected OS upload complications. All datalogger settings should be retained when updated remotely. If you choose to roll back to a previous operating system, the datalogger settings will be reset to default.

Watch the Video Tutorial: Sending an OS to a Local Datalogger.

CR1000X Web Browser Interface v.1.2 (970 KB) 13-09-2024

Standard Datalogger Web Browser Interface

Use this download to update the data logger's web browser interface.

To install this file, send it to the data logger using file control found in the Device Configuration Utility or file control found in LoggerNet.

This interface is recommended for fast IP interfaces like Ethernet and Wi-Fi. It does NOT perform well over slow communications mediums like cellular.

Note: This is NOT for system data loggers that have custom interfaces like the SunSentry, Hydro-Link, Alert205, and MeteoPV.

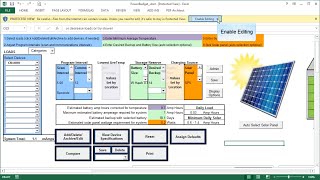

CPI Calculator v.1.0 (2.49 MB) 06-07-2016

The CPI Calculator is a downloadable Microsoft Excel spreadsheet used to estimate the usage and capacity of a CPI network. The calculator provides an overview on CPI devices including the CDM-A108, CDM-A116, CDM-VW300, CDM-VW305, and the CSAT3B. The calculator can also estimate the measurement speed of the CDM-A108 and CDM-A116 based on the number of channels and measurement parameters.

The CPI Calculator is an estimation tool and will help you better understand and design CPI networks by considering the following:

- What is the capability of each CDM or CPI device

- What is the CPI network capacity

- How much of the CPI capacity are the CDMs or CPI devices using

Custom Menu Example Program for Connections Video v.1 (1 KB) 26-03-2024

This program demonstrates creating a custom menu for data logger displays and corresponds to the Campbell Connections video: Creating Custom Menus in CRBasic for a Data Logger Display.

Data Logger Wiring Excel Template (1 KB) 26-03-2024

This is a data logger wiring diagram spreadsheet template that accompanies the Wiring Diagram Video. The spreadsheet includes templates for CR6, CR1000X, CR300, CR310, and CR350 data loggers. The file is an Excel template and works best with Microsoft Excel.

Casos de aplicación

In 2022, as Hurricane Fiona unleashed relentless rain on Puerto Rico, the Puerto Rico Landslide......leer más

Background Manitouwadge Municipal Airport is located 48 km (29.8 mi) north of highway 17 on Highway......leer más

The Homestake Neutrino Experiment—also referred to as the “Davis Experiment” after physicist Ray Davis, who......leer más

Overview In the fight against climate change, innovative solutions are emerging to address the global challenge......leer más

Background In 2022, ECR Medio Ambiente assumed the responsibility of overseeing the structural monitoring installation at......leer más

Overview In May 2019, the Government of Zambia embarked on the Climate Adaptation Water and Energy......leer más

Overview The Royal Chapel of Chaalis Abbey—often referred to as the “French Sistine Chapel”—is a treasure......leer más

Introduction At Campbell Scientific, we are committed to providing cutting-edge weather station solutions to organisations around......leer más