This product is not available for new orders. We recommend ordering: CPEC310.

| Services Available |

|---|

Resumen

The CPEC200 is a turn-key, closed-path eddy-covariance (EC) flux system for long-term monitoring of atmosphere-biosphere exchanges of carbon dioxide, water vapour, heat, and momentum. A complete system consists of a closed-path gas analyzer (EC155 closed-path gas analyzer with updated vortex intake design), sonic anemometer (CSAT3A sonic anemometer), datalogger (CR3000 datalogger), and sample pump. A valve module is also available for automated zero and span.

The gas analyzer’s intake design and small sample cell volume (5.9 mL) provide excellent frequency response (4.3 Hz cutoff frequency) with low total system power (12 W). Additionally, the vortex intake greatly reduces maintenance and maintains frequency response compared to traditional inline filters.

Leer másVentajas y características

- Fully integrated system with all the plumbing

- Low-power operation

- Excellent frequency response

- Optional automatic zero and span

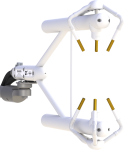

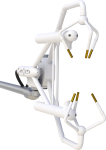

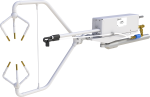

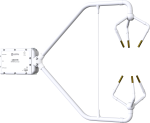

Imágenes

Descripción detallada

The gas analyzer’s small sample cell volume minimizes the sample residence time (50 ms at the system’s nominal flow rate, 7 LPM). This gives excellent frequency response (5.8 Hz half-power bandwidth) with low total system power (12 W).

Eddy-Covariance Measurements

CO2 and H2O are measured with an EC155 Closed-Path Gas Analyzer. Three-dimensional wind speed and sonic air temperature are measured with a CSAT3A sonic anemometer head.

CPEC200 System Enclosure

A fibreglass enclosure houses the datalogger, optional data storage peripheral, optional valve module, and the electronics that interface with the CPEC200 pump module. The CPEC200 system enclosure can be mounted to a tripod mast, CM106 tripod leg base, tower legs, or a large diameter pole.

CPEC200 Pump Module

The pump module, a standard component of the CPEC200 system, consists of a small dual-head diaphragm pump with a brushless DC motor mounted inside a fibreglass enclosure. An integral cable connects the pump module to the CPEC200 system enclosure, which provides power, temperature measurement and control, pressure measurement, and pumping speed measurement and control.

Valve Module (Optional)

Campbell Scientific offers two valve module versions. The basic three-valve module (pn #27559) enables the CPEC200 system to automatically perform zero, CO2 span, and H2O span measurements. The six-valve module (pn #26578) includes three additional valves to allow more CO2 span tanks to be measured. The valve module is housed inside the CPEC200 system enclosure. The outlet of the manifold has a proportional valve to automatically control the flow of zero/span gas.

Scrub Module (Optional)

A scrub module (pn #27423) is available for the CPEC200 which provides a zero air reference source for the CPEC200 without the need for an extra cylinder which can be useful in remote applications. The CPEC200 scrub modules pulls ambient air through three bottles of molecular sieve, effectively scrubbing CO2 and water vapour from ambient air to produce the reference zero. The scrub module and its small diaphragm pump are housed within a weather-tight fiberglass enclosure which is compatible with a variety of mounting options.

Preguntas frecuentes

Número de FAQs relacionadas con CPEC200: 10

Expandir todoDesplegar todo

-

The inserts prevent the tubing from collapsing as the ferrules are swaged onto the tubing. Although it is possible to make a leak-tight connection without an insert, the insert provides added protection against leaks. This is particularly true for tubes at negative pressure and for repeated tubing disconnect/connect cycles.

-

If the pump fails, it must be replaced. Contact Campbell Scientific for details. For the process of returning equipment to Campbell Scientific, refer to the Repair and Calibration page.

-

It is easy to learn how to cut tubing to length and swage the fittings. However, if it is preferred, order tubing assemblies cut to a specified length using pn 21823-L, Calibration Gas Tubing Assembly.

-

The threads on the nut and fitting have likely been damaged because they were over tightened. Replace both the nut and the fitting.

-

Yes. For more information, refer to the "CPEC200 Scrub Module Installation, Operation and Maintenance" appendix in the CPEC200 Closed-Path Eddy-Covariance System Instruction Manual.

-

The pump has a one-year warranty. Although the pump’s manufacturer does not specify an expected lifetime, the pump’s lifetime is expected to be significantly longer than one year.

-

Campbell Scientific recommends Synflex 1300 (pn 15702, Raw Plastic Tubing .250 in. OD). This tubing has a durable polyethylene jacket and an aluminum wrap to limit diffusion through the wall. The aluminum layer also makes this tubing easier to work with, as it does not tend to spring back into a coiled shape as much as other tubing types.

-

Yes. The 28549 comes with a field wireable plug (pn 28771) to make it easy to use an extension cord. Purchase an extension cord that is rated for outdoor use, and have a qualified electrician replace the female connector on the extension cord with the field wireable plug. This will avoid the issue of a power cord junction exposed to the environment.

-

Make sure the fitting is a ¼ in. Swagelok. It is possible that it is 6 mm instead. Metric fittings can be identified by the groove on the hex body of the fitting. If the fitting is 6 mm, replace the fitting on the regulator with a ¼ in. Swagelok, or use an adapter fitting.

-

Especificaciones

| Rango temperatura funcionamiento | -30° to +50°C |

| Rango voltaje entrada | 10.5 to 16.0 Vdc |

| Consumo |

|

System Enclosure |

|

| Dimensiones | 52.1 x 44.5 x 29.7 cm (20.5 x 17.5 x 11.7 in.) |

| Peso |

|

Pump Module |

|

| Inlet Connection | 3/8-in. Swagelok |

| Pumping Speed | 3 to 9 LPM (automatically controlled at the setpoint, typically 7 LPM) |

| Pressure Sensor Range | 15 to 115 kPa |

| Longitud de cable | 3.0 m (10 ft) |

| Dimensiones | 35.6 x 29.2 x 13.5 cm (14.0 x 11.5 x 5.3 in.) |

| Peso | 5.4 kg (11.8 lb) without mounting bracket |

Valve Module |

|

| Inlets for Three-Valve Module | Zero, CO2, span, and H2O span |

| Inlets for Six-Valve Module | Zero, CO2 span 1 to CO2 span 4, and H2O span |

| Outlets | Analyzer and H2O bypass |

| Connections | 1/4-in. Swagelok |

| Dimensiones | 14.0 x 12.7 x 14.0 cm (5.5 x 5.0 x 5.5 in.) |

| Weight of Three-Valve Module | 1.5 kg (3.3 lb) |

| Weight of Six-Valve Module | 1.9 kg (4.2 lb) |

Scrub Module |

|

| Consumo |

|

| Cylinder Volume | 480 cm3 each (29.29 in.3) |

| Molecular Sieve Size | 1.6 to 2.5 mm beads |

| Dimensiones armario | 39.4 x 34.3 x 20.3 cm (15.5 x 13.5 x 8.0 in.) |

| Peso | 9.6 kg (21.1 lb) |

Documentos

Folletos producto

Manuales

Documentos técnicos

Casos de aplicación

Conformidad

Misceláneo

- Performance Evaluation of an Innovative Sampling System for Closed Path Eddy Covariance Measurements

- Using Molecular Sieve to Zero Infrared Gas Analyzers for Eddy Covariance or Atmospheric Profile Measurements

- Field-Performance Verification of Carbon Dioxide, Water, and Nitrous Oxide Closed-Path Eddy Covariance Systems with Vortex Intakes Poster

Descargas

CR3000 OS v.32.07 (4.39 MB) 15-05-2024

Execution of this download installs the CR3000 Operating System and Compiler on your computer. It also updates the CR3000 support files for the CRBasic Editor.

Note: The Device Configuration Utility is used to upload the included operating system to the datalogger.

Upgrading from versions prior to version 28 of the Operating System will reset the datalogger’s CPU drive. This is due to a change in the format of the file system from FAT16 to FAT32. In order for the datalogger to operate correctly, as part of the upgrade, the CPU drive is formatted to FAT32. Any programs stored and running from the CPU drive will be lost. It is not recommended to update the datalogger’s Operating System over a remote connection where program control regulates the communication equipment (turning it on or off, etc.). In these cases, an on-site visit and a backup using DevConfig’s backup utility is necessary to update the datalogger’s Operating System.

Watch the Video Tutorial: Sending an OS to a Local Datalogger.

In all cases where the datalogger is being updated from an Operating System prior to 28, the use of DevConfig’s backup utility is recommended due to the CPU drive being formatted using the new FAT32 format.

CPEC200 CR3000 Program () 01-09-2011

Micrometeorology Group (435) 227-9100.

Device Configuration Utility v.2.32.01 (47.7 MB) 15-04-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

EC100 OS v.8.02 (560 KB) 14-10-2019

EC100 Operating System.

Watch the Video Tutorial: Updating the EC100 Operating System.

ECMon v.1.6 (10.7 MB) 29-03-2016

EC100-Series Support Software.

CSAT3H Heater Controller v.14.2 (46 KB) 02-02-2021

The CSAT3H Heater Controller ships with this encrypted program. This program is for the unlikely event that the program needs to be re-installed or updated to a newer version. Please contact Campbell Scientific if you have questions about the program or would like the algorithm modified for a specific application.

Casos de aplicación

The Warra long-term ecological research (LTER) site located in Southwestern Tasmania was founded in 1995......leer más

Forest habitats contribute more than any other terrestrial biome to carbon cycles and processes. It......leer más