Preprogrammed and low power

Resumen

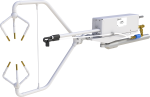

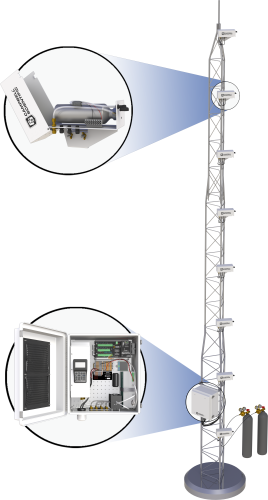

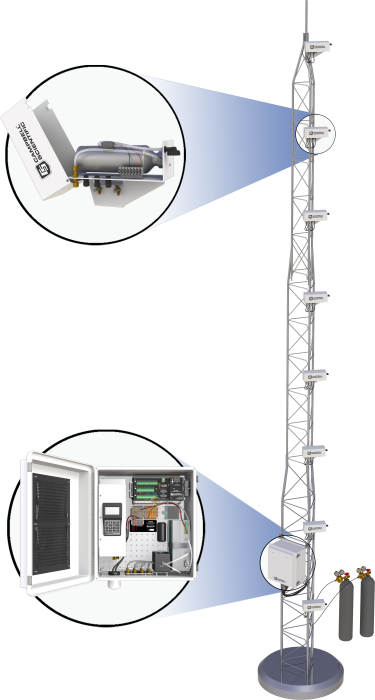

The AP200 is a complete, integrated CO2 and H2O atmospheric profile system. It measures carbon dioxide (CO2) and water vapor (H2O) concentration from up to eight intakes, which are normally spaced along the height of a tower to give a vertical profile. The AP200 is often used in conjunction with an eddy-covariance system to measure the storage term and provide you with a more complete measure of the surface gas exchange.

Leer másVentajas y características

- Fully integrated system

- Requires only 13 W (average at 25°C and 12 Vdc)

- Contains a Campbell Scientific CR1000X Measurement and Control Datalogger

- Automatically performs CO2 zero and span

- Automated temperature and pressure control

- Data logger program included

Imágenes

Descripción detallada

Measurements

Primary:

- CO2 concentration at each intake

- H2O concentration at each intake

- System diagnostic word

Secondary:

- Sample flow rate

- Sample cell pressure

- Sample cell temperature

- Other control variables

Note: Contact the Micromet Group at Campbell Scientific for questions or updates regarding the data logger program.

Productos similares

Preguntas frecuentes

Número de FAQs relacionadas con AP200: 53

Expandir todoDesplegar todo

-

Possibly. For example, to measure advection because of a drainage flow on sloping terrain, an AP200 system could be deployed with two towers, upstream and downstream along the slope, with four intakes on each tower.

-

The number of intakes required at a site depends on the characteristics of the canopy. For example, the canopy’s height and density directly affect the change in CO2 and H2O concentrations. Order enough intakes to accurately profile these concentration changes. The AP200 may be ordered with anywhere from four to eight intake assemblies.

-

The intake tubes can be quite long—up to a few hundred meters. Contact Campbell Scientific to ask about specific requirements for an application.

-

A dewpoint generator is used as an H2O standard. Dewpoint generators are laboratory instruments and are not suitable for long-term deployment in the field.

-

The intake heaters are wired in parallel, so that each heater sees a nominal 12 Vdc.

-

No. Because the AP200 has only eight inlets for air samples, it can only operate with a maximum of eight intake assemblies.

-

It depends on the type of chambers. The AP200 requires a constant flow of sample air for each intake, so it will not work with small chambers that require the air sample to recirculate. However, it might be possible to use the AP200 with chambers that allow a continuous sample flow to be extracted.

-

The spacing depends on the canopy and atmospheric conditions. It is important to know where the concentration gradients are the steepest.

For example, in a low agricultural crop canopy, it may be appropriate to use a logarithmic distribution within and near the top of the canopy, and a linear distribution above the canopy: 0.2 m, 0.4 m, 0.8 m, 1.6 m, 3.2 m (logarithmic) and 5 m, 7 m, 9 m (linear).

-

No. The AP200 requires flow from at least four intake assemblies for smooth operation of the pump.

Especificaciones

System Enclosure |

|

| Operating Temperature | -30° to +45°C |

| Power Requirements |

|

| Dimensions | 52.1 x 44.5 x 29.7 cm (20.5 x 17.5 x 11.7 in.) |

| Weight |

|

Pump Module |

|

| Pump Type | Dual-head diaphragm pump with a brushless dc motor |

| Mounting | Mounted in an insulated, temperature-controlled box inside system enclosure |

| Control | Pumping speed is automatically controlled to maintain the pump inlet pressure at the set point |

| Maximum Pumping Speed | 9.0 liters per minute (LPM) |

| Pressure Sensor Range | 15.0 to 115.0 kPa |

| Heater | 8.0 W (turns on/off at 2°C) |

| Warm-up Time | ~50 min (from -30° to +2°C) |

| Fan | 0.7 W (turns on at 50°C and off at 45°C) |

Valve Manifold |

|

| Mounting | Mounted inside system enclosure |

| Inlets | Eight air sample inlets plus one inlet for zero, one inlet for CO2 span, and one inlet for H2O span |

| Connections | 0.25-in Swagelok |

| Mass Flow Sensor | 0 to 1.0 standard liters per minute (SLPM) |

| Heater | 8.0 W (turns on/off at 5°C) |

| Warm-up Time | ~20 min (from -30° to +4°C) |

| Fan | 0.7 W (turns on at 45°C and off at 43°C) |

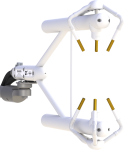

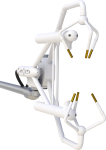

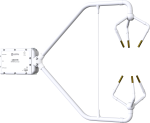

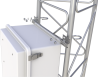

Intake Assembly |

|

| Filter | 1.0-in diameter, sintered stainless-steel disk filter, 10-micron pore size |

| Orifice Heater | 2 kohm (0.07 W at 12 Vdc) |

| Mixing Volume | 750 mL |

| Sample Connection | 0.25 in. Swagelok |

| Number of Connections for Heater Cable Entry Seals | 3 (1 in, 2 out) |

| Cable Diameter for Heater Cable Entry Seals | 2.8 to 6.6 mm (0.11 to 0.26 in.) |

| Wire Diameter for Heater Cable Screw Terminals | 26 to 12 AWG |

| Wire Stripping Length for Heater Cable Screw Terminals | 5.0 mm (0.2 in.) |

| Screw Tightening Torque for Heater Cable Screw Terminals | 0.4 N•m |

| Orifice Inside Diameter | 0.178 mm (0.007 in.) |

| Dimensions | 31 x 12.5 x 19 cm (12 x 5 x 7.5 in.) |

| Weight | 1.4 kg (3.1 lb) |

Documentos

Folletos producto

Casos de aplicación

Conformidad

Descargas

AP200 CR1000 Program v.2.01 (31.3 KB) 12-01-2021

AP200 CR1000(X) Program.

Compatible with the LI-850.

Note: For those with the LI-840 contact Campbell Scientific for compatible code.

Device Configuration Utility v.2.32.01 (47.7 MB) 15-04-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

Casos de aplicación

This case study discusses the integration of CPEC310 and AP200 systems to explore the theories......leer más

The Warra long-term ecological research (LTER) site located in Southwestern Tasmania was founded in 1995......leer más