Fundamentos Estaciones meteorológicas automáticas

- ¿Que es una estación meteorológica automática?

- ¿Cuales son los componentes de una estación meteorológica automática?

- ¿Dónde se puede utilizar una estación meteorológica automática?

- ¿En que se diferencia una estación meteorológica automática de otra?

- ¿Cómo escoger la estación meteorológica automática adecuada para su aplicación?

¿Que es una estación meteorológica automática?

Una estación meteorológica automática es un sistema integrado de diversos componentes utilizados para medir, registrar y transmitir variables meteorológicas, como temperatura, velocidad y dirección del viento, radiación solar y precipitación. Las estaciones meteorológicas se utilizan en tierra y mar para diversos fines operativos y de investigación. El diseño robusto, bajo consumo eléctrico y los métodos de comunicación a larga distancia permiten que las estaciones meteorológicas modernas funcionen de forma remota durante largos períodos sin necesidad de intervención humana.

Las estaciones meteorológicas varían enormemente en su nivel de sofisticación y complejidad, así como en su flexibilidad y capacidad para medir, monitorear y estudiar el clima y las condiciones climáticas. Por ejemplo, algunas estaciones meteorológicas requieren la recogida manual de los datos medidos, mientras que otras estaciones meteorológicas están altamente automatizadas.

La lectura manual y registro de las medidas meteorológicas se puede realizar visitando el sitio donde se encuentra la estación meteorológica, viendo los valores medidos y registrando los datos manualmente, o utilizando un dispositivo electrónico de mano. Este proceso puede ser una buena solución para campañas de monitorización meteorológica a corto plazo o para mediciones poco frecuentes. Sin embargo, para mediciones frecuentes, monitorización a largo plazo, monitorización remota o mediciones en múltiples ubicaciones, el registro manual no sería lo más adecuado y requiere mucho trabajo. Además algunas ubicaciones pueden plantear problemas de seguridad para el personal.

Las estaciones meteorológicas automáticas miden y registran variables meteorológicas durante largos períodos de tiempo sin la necesidad de intervención humana. Ofrecen la comodidad de un monitoreo desatendido a largo plazo en múltiples ubicaciones remotas, reduciendo así el tiempo y coste asociados. Además, se minimiza la posibilidad de error humano en la recolección de datos. Para más información, revisa la siguiente fuente: Bertrand D. Tanner, “Automated Weather Stations,” Remote Sensing Reviews 5, no. 1 (1990): 73-98.

La durabilidad y bajo consumo de las estaciones meteorológicas automáticas son una buena opción en lugares con climas severos y remotos. Algunas estaciones meteorológicas automáticas son tan versátiles que pueden configurarse de muchas maneras para registrar, monitorear y estudiar los patrones climáticos a lo largo del tiempo, así como cambios climáticos regionales. De hecho, los datos de una red de estaciones meteorológicas automáticas, como una mesonet, pueden transmitirse a un servidor centralizado donde los datos se compilan, revisan, analizan y comparten.

En este informe, nuestro enfoque se basa en estaciones meteorológicas automáticas que miden y registran variables meteorológicas durante períodos prolongados, sin la necesidad de intervención humana, en lugar de las estaciones que requieren intervención manual.

¿Cuales son los componentes de una estación meteorológica automática?

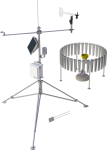

Una estación meteorológica automática (AWS) está formada por varios componentes, que trabajan juntos para medir, almacenar y comunicar las variables meteorológicas. Las estaciones meteorológicas automáticas pueden variar mucho en su diseño. Por ejemplo, un dispositivo autónomo simple y limitado serviría para un uso personal Sin embargo, una estación de grado científico más sofisticada, estará formada por varios componentes, proporcionando así una solución personalizada adecuada las necesidades. Los componentes de una estación meteorológica automática a medida podría incluir lo siguiente:

- Sensores

- Data logger

- Comunicaciones (almacenamiento y descarga de datos)

- Software

- Alimentación eléctrica

- Armario intemperie y herrajes

Sensores

Algunos de los sensores habituales en estaciones meteorológicas automáticas, y los parámetros que miden, serían los siguientes:

| Sensor Type | Parameter Measured | Example Sensor |

|

Anemómetro |

Velocidad viento |

|

|

Barómetro |

Presión barométrica |

|

|

Higrómetro |

Humedad relativa |

|

|

Potenciómetro/veleta |

Dirección viento |

|

|

Piranómetro |

Radiación solar incidente |

|

|

Pluviómetro |

Lluvia o nieve |

|

|

Radiómetro |

Radiación incidente o reflejada por una superficie |

|

|

Termómetro (termistor, termopar, RTD) |

Temperatura |

|

Cada sensor está diseñado para medir uno o varios parámetros, convertir cada medida en una señal eléctrica y transmitir la señal al datalogger. La señal eléctrica se transmite normalmente a través de los cables del sensor, lo cual puede requerir conectores especiales. Alternativamente, la transmisión se puede realizar de forma inalámbrica.

La cantidad de cables o el tipo de conector que utiliza el sensor depende del tipo de señal que el sensor emite. El tipo de señal, a su vez, varía entre los diferentes sensores. Algunos tipos de señales comunes incluyen voltaje, corriente, pulsos, digital y serie. Cuando las interfaces inalámbricas están integradas en el sensor, el datalogger debe tener un dispositivo inalámbrico equivalente.

Data logger

Nota: Técnicamente, en una estación meteorológica automática, en lugar de un datalogger se podría usar un dispositivo de medida y control como un PLC (controlador lógico programable) o RTU (unidad de terminal remota). Sin embargo, nuestro enfoque se basa en el uso de dataloggers de propósito general, que ofrecen mucha más flexibilidad a la estación meteorológica automática. Por ejemplo, un datalogger es fácil de instalar en campo para monitorización remota, es lo suficientemente resistente para uso en el exterior de forma continua, y tiene bajo consumo.

El datalogger se puede programar para que muestree los sensores repetidamente cada intervalo de tiempo (la velocidad de muestreo), o bajo condiciones específicas o después de que ocurra algún evento en particular (como que se produzca lluvia). Un datalogger avanzado recibe las señales eléctricas de los sensores, realiza cálculos programados, procesa los datos según sea necesario y almacena los datos resultantes en su propia memoria. Además, el datalogger puede realizar operaciones de control, similares a un PLC o RTU.

La señal de salida del sensor debe ser compatible con el canal de entrada del datalogger al que está conectado. Un datalogger puede tener diferentes tipos de canales de entrada y adaptarse a diferentes tipos de sensores, así como disponer de instrucciones predefinidas para sensores utilizados comúnmente. Existen módulos adicionales para aumentar el número de canales tanto de entrada como salida.

Comunicaciones (almacenamiento y descarga de datos)

Se pueden utilizar diversos métodos para guardar los datos adquiridos del datalogger, así como para transferir los datos y valores calculados a un PC u otro dispositivo. Estos métodos emplean variedad de periféricos de comunicaciones, tanto para opciones in-situ como por telecomunicaciones remotas.

- En ocasiones, el datalogger se conectará directamente al PC o un portátil. Otras opciones serían mediante memoria flash USB, tarjetas microSD o soluciones específicas del fabricante.

- En muchas situaciones lo óptimo será usar un periférico de comunicaciones que permita comunicaciones remotas para la descarga de datos. Hay opciones de telemetría remota por cable (Ethernet, red multipunto, satélite, módem de corto recorrido, teléfono fijo y teléfono sintetizado por voz), así como opciones inalámbricas (radiofrecuencia, teléfonía celular y Wi-Fi)

Software

Para ayudar a compartir, analizar y sacar informes con los datos adquiridos por el datalogger, se utiliza software especializado. Los paquetes de software permiten:

- Desarrollo de aplicaciones personalizadas para comunicar con los dataloggers

- Creación y edición de programas para el datalogger

- Descarga de datos en la nube

- Organización y almacenamiento de datos en bases de datos

- Distribución de datos PC-a-PC

- Comunicaciones con dispositivos iOS o Android

- Displays gráficos de datos de múltiples dataloggers en una única página web

Fuente alimentación

Para que una estación meteorológica automática funcione, es necesario contar con una fuente de alimentación fiable. Cuando se instala una estación en una ubicación sin acceso a la red de 220Vac, normalmente se utiliza una batería recargable. El número y capacidad de las baterías necesarias dependerá del consumo de corriente (o los requisitos de alimentación) de la estación meteorológica automática (incluida la telemetría), de los intervalos entre mantenimientos, y de las horas de sol disponibles a esa latitud.

Las pilas alcalinas requieren ser sustituidas, y una batería recargable requiere recarga. La recarga de una batería se hace mediante un regulador y una fuente de carga. La fuente de carga puede ser un transformador de AC o un panel solar. (La alimentación eléctrica de una estación meteorológica automática se puede complementar con una batería recargable externa, que también se recarga con un regulador y una fuente de carga). Algunas veces se utilizan turbinas eólicas, celdas de combustible o generadores diesel o gasolina como fuentes de carga.

Armario intemperie y estructura de montaje

Para proteger de la intemperie los componentes más sensibles de la estación meteorológica automática, se usa un armario intemperie del tamaño adecuado, donde en su interior se instala el datalogger, periférico de comunicaciones, fuente de alimentación y posiblemente algún sensor. Los componentes de la estación meteorológica se agrupan y fijan en una estructura metálica estable, como un trípode, una torreta o una boya. Disponemos de una gama amplia tanto de armarios intemperie como de estructuras soporte.

¿Dónde se puede utilizar una estación meteorológica automática?

Si bien muchas estaciones meteorológicas automáticas están diseñadas para ser instaladas en climas moderados, algunas están diseñadas específicamente para condiciones ambientales extremas. Estos entornos extremos pueden ser terrenos montañosos, desiertos, selvas, minas, océanos y témpanos de hielo. La estación meteorológica automática a menudo se deja desatendida durante largos períodos para que procese y registre automáticamente los datos medidos de diversos sensores hasta que finaliza el período de monitoreo, que puede ser décadas más tarde.

La estación meteorológica automática toma datos meteorológicos de un lugar específico, o puede formar parte de una red de estaciones meteorológicas (como una mesonet) y tomar datos de un área geográfica mucho más extensa.

¿En que se diferencia una estación meteorológica automática de otra?

Si bien las estaciones meteorológicas automáticas se pueden comparar y contrastar a muy diferentes niveles, las siguientes son algunas de las características principales que pueden ser útiles a tener en cuenta:

- Calidad

- Flexibilidad y ampliación

- Tipo de instalación

- Configuración

Calidad

Es importante tener en cuenta que los fabricantes no utilizan los mismos criterios para clasificar las estaciones meteorológicas automáticas. Por ejemplo, una estación considerada como un instrumento “profesional” puede ser considerada por otro fabricante como adecuada solo para uso particular (como un aficionado que monta una estación en la terraza). Dado que la terminología utilizada para clasificar las estaciones meteorológicas automáticas no es consistente, no se debe confiar únicamente en la diferenciación entre estaciones meteorológicas automáticas. Sinó que lo importante es entender para que se quiere, así como su ubicación, y considerar las características relacionadas con la calidad, y que afectan el probable éxito de la estación para cumplir ese propósito.

Las siguientes características relacionadas con la calidad de una estación meteorológica automatizada, que se explican en las siguientes secciones, pueden afectar su rendimiento y el cumplimiento de las expectativas:

- Calidad de la medida (precisión, repetibilidad y resolución)

- Fiabilidad

- Vida útil

Calidad de la medida

La precisión, repetibilidad y resolución son términos que a menudo se confunden y se usan de manera incorrecta al describir la calidad de la medida. A continuación se detalla brevemente el significado de estos términos:

- Precisión es la capacidad de una medida a dar un resultado lo más cercano posible al valor real.

- Repetibilidad es la cantidad de medidas iguales obtenidas al repetir la medida.

- Resolución es el cambio más pequeño que es detectable.

Aunque la calidad de una estación meteorológica automática se refleja en su precisión, repetibilidad y resolución, estas características no están directamente correlacionadas. Por ejemplo, una estación meteorológica automática puede proporcionar medidas con buena repetibilidad, sin embargo pueden ser medidas poco precisas.

Las estaciones meteorológicas automáticas se construyen para diferentes propósitos. Por ejemplo, una estación simple que registra la temperatura y humedad del aire exterior con una baja calidad de medida (precisión, repetibilidad y resolución) puede satisfacer las necesidades de un aficionado a la meteorología. En cambio, una organización cuyo objetivo o negocio principal es obtener y distribuir información meteorológica, necesitará una estación meteorológica más sofisticada con mejor calidad de medida, que registre no solo la temperatura y humedad del aire, sino también la presión barométrica, la precipitación, la dirección del viento, velocidad del viento, y otros parámetros.

Fiabilidad

La fiabilidad o consistencia a lo largo del tiempo de las medidas meteorológicas realizadas por un aficionado a la meteo puede no ser un factor crítico, ya que con datos intermitentes puede tener suficiente. Sin embargo, no sería aplicable a una agencia meteorológica nacional que necesita los datos minuto a minuto, constantes y sin pérdidas.

Vida útil

La vida útil es un factor crítico según lo que se quiera obtener de la estación meteorológica automática. Un aficionado que se ha gastado poco dinero en la estación, seguramente no le preocupe si comienza a obtener medidas erróneas o si la estación falla por completo y se compra una nueva. Sin embargo para una agencia meteorológica, que se ha gastado mucho dinero en la estación, espera que esta le proporcione buenos datos durante muchos años.

Flexibilidad y capacidad de expansión

En muchos casos, la flexibilidad y la capacidad de expansión de una estación meteorológica automática la determina el modelo de datalogger.

- Algunos dataloggers solo hacen lo que llevan preprogramados de fábrica. Pueden escanear sensores y registrar medidas a intervalos prefijados por el fabricante.

- Otros dataloggers son configurables dentro de ciertas limitaciones. Puede disponer de opciones para seleccionar intervalos.

- Otros dataloggers permiten ser programados por el usuario. Mediante un lenguaje de programación, uno puede definir los intervalos de muestreo y almacenamiento, definir condiciones y ejecución en función de algún evento concreto (por ejemplo si se produce lluvia).

Por otro lado, los dataloggers varían en función de la compatibilidad con sensores. Algunos dataloggers solo son compatibles con sensores del propio fabricante o de modelos muy concretos, y otros admiten gran variedad de sensores de múltiples fabricantes o tipos de señal.

Los dataloggers que ofrecen flexibilidad y capacidad de expansión se diferencian en el número de canales (que determina cuantos sensores y otros dispositivos se pueden conectar), así como los tipos de canales que ofrecen (determina los tipos de sensores y otros dispositivos que se pueden conectar). Las necesidades puntuales y de expansión futuras, se pueden abordar seleccionando un datalogger con un módulo de ampliación de canales (por ejemplo un multiplexor).

La flexibilidad en un datalogger permite quitar o agregar sensores según sea necesario para adquirir las medidas deseadas cuando sean necesarias.

Método instalación

Las estaciones meteorológicas automáticas pueden ser portátiles o de instalación permanente. Es importante tener en cuenta que los términos "portátil" y "permanente" se pueden usar para cubrir una amplia gama de estaciones que varían mucho en cuanto a su robustez y estabilidad. Por ejemplo, una estación etiquetada por un fabricante como "portátil" puede ser, de hecho, más resistente que la estación "permanente" de otro fabricante.

Estaciones portátiles

Por lo general, una estación meteorológica automática portátil es la que se puede mover fácilmente de un sitio a otro. (Sin embargo, si es necesario, una estación portátil puede instalarse de forma permanente en un sitio). Normalmente se instala en un trípode fijado directamente al suelo. Se puede aumentar la estabilidad usando vientos.

Algunas aplicaciones requieren una estación portátil que se pueda configurar rápidamente para monitorear las condiciones meteorológicas en un período corto de tiempo. Una estación portátil se usaría por ejemplo en quemas controladas para monitorizar el viento y ayudar a garantizar que los incendios permanezcan controlados. Otro ejemplo sería para monitorizar las condiciones del suelo y variables meteorológicas en la manipulación de productos químicos por posibles derrames u humos peligrosos.

Estaciones permanentes

Una estación meteorológica automática permanente está diseñada para permanecer en un sitio durante un período prolongado (si es necesario, también se puede mover a otro sitio). Habitualmente se utiliza una torreta metálica, que se fija al suelo sobre una base de cemento.

Configuración

Las estaciones meteorológicas automáticas varían segun el grado de configuración, lo que hará que su disponibilidad sea más o menos inmediata:

- Una estación llave en mano requiere una configuración mínima después de sacarla del paquete, ya que solo se puede operar de una manera.

- Una estación precableada o preconfigurada se entrega con un conjunto de sensores cableados al datalogger, y admite alguna posibilidad de configuración.

- La estación a medida, incluye sensores escogidos por el usuario que satisfagan las necesidades de la aplicación, y los sensores no estan precableados al datalogger. Esta estación es la más configurable.

¿Cómo escoger la estación meteorológica automática adecuada para su aplicación?

Selecting an automated weather station is an important decision that requires careful consideration. For assistance with the selection process, review the detailed Purchase Considerations section.

La selección de una estación meteorológica automática es una decisión importante que requiere pensarlo bien. Para más ayuda en el proceso de selección, revise la sección de Consideraciones de compra.

Consideraciones de compra para Estaciones meteorológicas automáticas

An automated weather station is built at the component level to provide an organization with the instruments it needs to meet its measurement objectives. The versatility of an automated weather station is evidenced in your ability to add, remove, or substitute sensors or other peripherals as your data measurement and monitoring needs change.

To assess the numerous research-grade automated weather station models and ultimately determine which components are the most suitable, you should first identify your application's needs and requirements. If necessary, review any related documentation, permits, or regulations. Your familiarity with these items will help ensure that the automated weather station components you select will meet your compliance requirements. For more information, review the following source: Bertrand D. Tanner, “Automated Weather Stations,” Remote Sensing Reviews 5, no. 1 (1990): 73-98.

Note: The considerations discussed here do not constitute an all-inclusive list but serve to provide common considerations that have been helpful to our customers in guiding them through the selection process.

Measurement Requirements

Selecting the appropriate sensors is a critical step for your organization to obtain the data it requires. Different sensor types require different input types on the data logger that can interpret the sensors' signals.

| Sensor input types | Determine which parameters you need to measure, which will then determine the sensor types that you need. Review the manual for each sensor you will use to ascertain the type of data logger connection needed. (The manual should also provide information about how to wire the sensor to the data logger.) |

| Number of sensors | Data loggers vary greatly in both the quantity and types of connections (analog or digital) they offer for sensor inputs. You will need to ascertain how many sensor inputs of each sensor type your data logger needs to accommodate your application. |

| Expansion | An expansion peripheral can enable multiple sensors to share the same data logger connection, which can significantly expand the number and types of sensors your data logger can measure. If the number or types of sensors you will be using exceeds the inputs available on a data logger, you may be able to use a compatible expansion peripheral. Moreover, consider how your organization's long-term goals may differ from the current goals and require additional inputs and/or outputs on the data logger. While planning for future needs upfront may incur additional cost, additional equipment costs or downtime will not be incurred later. |

| Compatibility | You may already own sensors that you plan to use in your automated weather station. Ensure that these sensors are compatible with the data logger you are using. |

Campbell Scientific automated weather stations are modular, enabling the connection of a variety of sensor types and peripherals to customize a station that best meets your application's needs.

Measurement Quality

Whereas precision and resolution of an automated weather station may be directly related to the performance of the data logger, the station's accuracy is often determined by its least accurate component.

| Accuracy | Accuracy is the ability of a measurement to provide a result that is as close as possible to the actual value. For example, a data logger that produces a measurement within ±0.1 of the actual value is said to be more accurate than a data logger that produces a measurement within ±0.5 of the actual value. Because the overall accuracy you can attain is determined by the least-accurate component in your automated weather station, check that your components provide a suitable accuracy level for your requirements. Note that accuracy levels differ depending on the temperature range. |

| Precision | Precision is the amount of agreement between repeated measurements of the same quantity. For example, a data logger that produces 10 measurements of the same sample within ±0.1 of each other is said to be more precise than a data logger that produces 10 measurements of the same sample within ±0.8 of each other. Match the level of precision of your data logger with your measurement data needs. |

| Resolution | In measurements, resolution refers to the smallest change in a quantity that can be detected. For example, a data logger that detects a difference to the nearest tenth of a millivolt is said to have a higher resolution than a data logger that detects a difference to the nearest millivolt. To improve your absolute resolution, use the lowest/smallest fixed voltage range possible that will cover the output range of the sensor being measured. |

Campbell Scientific instruments are reputed to provide high levels of accuracy, precision, and resolution in terms of measurement data.

Site Environment

Your automated weather station's location should be representative of the general area of interest that you would like to measure. If the components of your automated weather station are not designed for the environment in which they are located, the instruments may not perform as expected or stop working.

| Extreme temperatures | The high and low temperatures at your site will determine whether you can use equipment with a standard operating temperature range. If your site's high and low temperatures are beyond the temperature capability of specific components, select components with an extended temperature range. |

| Quality and durability | If the site for your automated weather station is exposed to icing, sand, blowing dirt, salt spray, snow buildup, high winds, hail, or heavy rain, ensure your station's components are durable enough to withstand these conditions. (For example, if a significant amount of snow covers the station's components or slides down next to them, the snow's pressure and weight may cause the mounting structure to crumple.) Assess the quality and durability of your equipment and the likelihood that it will fail. The failure of one component may affect other components and the quality of the collected data. |

| Obstructions | If there are obstructions near your automated weather station, you may need to select mounting options that ensure your measurements aren't adversely affected. For example, you may need to use a taller mounting structure to raise your measurement height. For more information, review the Weather Station Siting web page. |

| Man-made damage | Consider how susceptible the site location is to man-made risks such as off-road vehicles, golf balls, or bullets. As necessary, camouflage your automated weather station to make it less attractive to potential vandals. |

| Wildlife interference | Station performance and data accuracy can be affected by a bird that views a rain gage as the perfect home for its new nest. Select sensors that are designed to prohibit wildlife interference. For example, select a rain gage with a spike strip to prevent birds from nesting in the gage. |

| Water exposure | If your automated weather station will be placed in a humid or wet environment, check that the components can handle the moisture level and possible corrosion from salt spray. You can protect your data logger and other sensitive components by housing them inside a sealed environmental enclosure. If applicable, select an enclosure and connectors that are corrosion resistant, or eliminate the use of connectors completely by terminating the sensors inside the enclosure. Select an enclosure of a suitable size to house the necessary components. To keep the inside of the enclosure dry, use desiccant. Either schedule maintenance intervals to replace the desiccant, or measure the internal enclosure humidity (using an enclosure humidity sensor or a replacement humidity indicator card) to determine when replacement desiccant is needed. |

| Lightning | If your automated weather station is in a lightning-prone area, equip the mounting structure with lightning-protection measures. |

| Vibration | If your automated weather station will be subjected to vibrations—such as from mines or construction sites—ensure your components are designed to endure those conditions and mitigate potential measurement errors. |

| Multi-function use | If the site for your automated weather station could be used to provide different measurement data for different seasons, equip your station with the appropriate sensors. For example, outfit your station to provide fire-weather measurement data in the summer and avalanche-forecasting data in the winter. |

Campbell Scientific equipment is designed to be rugged—even in harsh, remote environments or in applications requiring unattended, automated, long-term monitoring.

Monitoring Duration

The length of the intended measurement and monitoring period may determine whether a portable or permanent automated weather station is needed.

| Portability | Decide whether an automated weather station will remain in a fixed position or if it will be transported from site to site. This will help you determine whether a permanent or portable station installation is appropriate. A portable weather station can be moved easily among multiple sites that require infrequent or temporary monitoring and measurement. A drawback to a portable station is that it may not have the necessary reinforcement or guying intended for a station that is deployed for decades and eventually exposed to extreme conditions. |

| Footprint | Because of the way a portable weather station is anchored (typically using a guy wire kit), it may have a larger footprint than a permanent weather station. Ensure that the intended site location can spatially support the mounting of your selected automated weather station. |

Campbell Scientific offers both portable and permanent automated weather stations.

Programming Flexibility

Programmable data loggers offer options for scheduling scans, as well as developing and running customized programs.

| Measurement flexibility | A programmable data logger can be scheduled to scan a sensor based on a programmed scan rate, under specified conditions, or in response to an event. Some data loggers don't require the recording of every single measurement from the scans. For example, if a sensor is scanned every five seconds (the scan rate), only an average reading for a 15-minute period (the sample rate) may need to be recorded. Make sure the data logger you select has a level of flexibility appropriate for your needs. If your application requires a higher scan rate, which uses more power, ensure that the station's power supply is sufficient to meet those demands. |

| Programming language | While some data loggers are hard-coded to only perform a core set of functions, other data loggers have a built-in, full programming language to allow users the flexibility to develop and run their own customized programs. Determine the skill level of the user who would potentially program the data logger, as well as the needs of your facility to develop its own programs. Select a data logger that will match well. |

| Onboard processing | A sophisticated data logger may have onboard algorithms that can calculate daily minimums, maximums, averages, totals, or other statistical values. Moreover, parameters such as the following may be calculated using the data provided by sensors: density altitude, dew point, evapotranspiration, heat index, and wind chill. |

| Data storage flexibility | By providing onsite statistical and mathematical processing, a sophisticated data logger can record just the calculated values rather than all the measurement values. This minimizes the amount of data that needs to be stored and transmitted by the data logger, prolonging the time before your data logger's memory becomes full and the data need to be downloaded. In addition, with less data, the cost to retrieve the data may be reduced (depending on the method used), and the data analysis or review process may be simplified. |

| External device control | Some data loggers can be programmed to control external devices, such as activating a device at a preset time or in response to a measured condition or event. Data loggers can activate or shut down motors, gates, pumps, purifiers, valves, injectors, etc. If you need the data logger to control external devices, verify that the data logger, or the data logger combined with a terminal expansion peripheral, has this capability. |

Campbell Scientific data loggers are backed by a built-in, full programming language to enable the customization of programs for your automated weather station application. In addition, a free, menu-driven, PC-compatible software package that simplifies the creation of data logger programs is available for download.

Data Storage

The value of your measurement data lies not merely in its collection, but in your ability to use the data when, where, and how you need to, such as transferring data to databases or directly to users; closely watching the real-time data; monitoring averages, maximums, and minimums; reviewing a set of historical data; or looking for trends or patterns over a longer period.

| Frequency of scans and records | Knowing how frequently the sensors are scanned, and how frequently data measurements and/or calculated values are recorded, provides helpful information in determining how long a data logger can record data before the memory capacity becomes full and requires downloading. |

| Storage capacity | Selecting a data logger by memory size alone may not prove advantageous. Instead, it may be more beneficial to consider storage capacity in terms of how many readings the data logger can store. It is possible for a data logger to have many kilobytes or megabytes of memory but only be able to hold a small quantity of readings. Review the data logger's specifications for both the memory size and the quantity of readings the data logger can store. If the data logger's onboard memory capacity is not sufficient for your project, find out if compatible memory expansion peripherals are available. |

| Memory type | Review the specifications for a data logger to determine if it uses fill and stop memory, or if it uses ring memory. This can help you determine how frequently your facility needs to download the data, and then you can schedule your data retrieval accordingly. |

| Battery-backed data storage | If a data logger loses power because of a power failure or from being powered down, it is necessary to ensure that your data will not be lost as a result. Different types of storage media provide different protection in this regard.

If you anticipate that the power supply to your data logger may experience frequent planned or unplanned power outages, select a data logger with either a non-volatile data storage medium or with a battery-backed volatile data storage medium. |

Campbell Scientific offers numerous communication peripherals to assist with the data storage needs of your automated weather station.

Communications Needs

The ability of a data logger to communicate with other components in your automated weather station depends on the communication protocols the data logger uses, the data logger's integrated communication capabilities, and the data logger's compatibility with communication peripherals.

| Communication protocols | Data loggers vary in their support of the different communication protocols available, such as DNP3 or Modbus. Review the data logger's supported protocols to determine if the data logger shares a common communication protocol with your other station components. |

| IP communications | Determine if the data logger has integrated IP communication capabilities, such as an integrated Ethernet terminal, or if it can be integrated with an external communication peripheral. |

| Remote or direct access | If it is important for you to collect and view your data without having to visit your site, investigate the telemetry options available to you. If remote access is not a concern for you, consider your onsite options. |

| Onsite options | Depending upon the limitations of your station site, you may have to rely on onsite options such as cables connecting the data logger directly to a PC or laptop. Another onsite option is to use an external data storage device with a memory card that can be transported and uploaded to a PC at an offsite location. Check the compatibility of the data logger with the various data retrieval and communication options you are considering. If you need to use a cable to connect your data logger and computer, calculate the cable length you need. A standard RS-232 cable may only come in a length of 50 feet. To increase the connection length up to a few thousand feet, a converter is needed. |

| Telemetry | If wireless transmission is available, you can use a telemetry peripheral to transmit data remotely. The following are some possible telecommunication options: Ethernet, multidrop network, radio frequency (RF) network, satellite system, short haul modem, landline phone, voice-synthesized phone, and cellular phone. Check the compatibility of the data logger with the various data retrieval and communication options you are considering. Each telecommunication option has its own requirements that should be reviewed. For example, review the transmission distance or area of each option, as well as its applicable service requirements. You may find that a particular option is not available or does not provide the coverage you need. |

| RF network | If you would like to use a radio frequency (RF) network, investigate whether an FCC license is required. If there are line-of-sight obstructions, such as mountains, consider using a repeater station to enable the base station to receive data from the field station(s). |

| Notifications and alarms | Using a communication peripheral, some data loggers may be programmed to send regular notifications to personnel regarding the current conditions at the site. In addition, if an atypical event occurs, a data logger can be programmed to trigger an alarm (such as a phone call, bell, whistle, light, etc.) to notify personnel who can make any necessary decisions and adjustments. Determine which parameters the data logger will use to automate notifications or alarms, and ensure that the data logger can be suitably programmed. |

| Onsite display | Some data loggers offer a built-in keyboard and display, and other data loggers may offer a separate, portable keyboard and display screen. Personnel can use these devices to respond to prompts and messages from the data logger at the station site. Instead of using a keyboard with display to interact with an onsite data logger, it may be possible to use a laptop computer. |

Campbell Scientific data loggers offer a variety of communication protocols and the capability to interface with diverse communication peripherals.

Power Requirements

To provide continuous monitoring, automated weather stations require a power supply that is sized to meet the total power requirements of the station. The power supply must be sufficient to handle the current drain of all the sensors, data logger, communication peripherals, and other equipment.

| Power requirements | Review the listed power requirements of your components to understand their typical current drain for both active and quiescent states. If your automated weather station includes equipment with a high current drain, such as cellular phones or satellite transmitters, select a large-capacity rechargeable battery pack. |

| Power distribution | Some data loggers can provide the power to operate sensors and other devices. |

| Sensor control | To reduce power drain, consider selecting a data logger that is able to switch the sensor power on only when a reading is taken. |

| Availability issues |

|

| Supplemental and backup power | Power to an automated weather station can be supplemented with an external rechargeable battery, which is recharged using a regulator and a charging source. If your automated weather station will use an ac power supply, consider the benefits of a backup battery. |

| Power budget | Whatever power source is used, ensure that you will have enough power supply for continuous sampling. Estimate the power requirements of all the components of your automated weather station using a power budget. |

Campbell Scientific devices are designed to be low-power-consuming, and numerous power supply options are available. To conduct your power budget, you can use these resources:

- "How Much Power Does Your Data Acquisition System Need?" blog article

- "Power Budget Spreadsheet"

- "Power Budgeting" video

Setup

Turnkey, prewired or preconfigured, and custom automated weather stations differ in the ease with which the stations can be set up, as well as how much latitude there is regarding the ability to set them up in a particular way.

| Turnkey | A turnkey automated weather station is typically sold as a one-size-fits-all instrument and is, therefore, limited in its configurability. For example, it cannot be customized to meet the needs of an application or site. However, because a turnkey station requires very little or no configuration prior to usage, it can be set up quickly. |

| Prewired or preconfigured | A prewired or preconfigured automated weather station installation with a standard suite of prewired sensors can provide an easy selection option for an organization with compatible measurement needs. This type of station installation is more simplified than that of a custom installation. Consequently, it minimizes the wiring time and possibility of erroneously connecting a sensor to the wrong input terminal. |

| Custom | For an organization with specialized needs or the desire for maximum configurability, a custom automated weather station installation may be an appropriate option. Because the sensors are hand-selected, an organization can choose sensors that meet their needs for accuracy, precision, reliability, and durability. Sensors can be added and removed as needed based on changes to research or project objectives, or funding. However, configuring a custom automated weather station requires the user to have some level of technical knowledge or experience to install and configure each sensor separately. |

Campbell Scientific offers turnkey, prewired or preconfigured, and custom automated weather stations.

Mounting

An automated weather station's components, whether housed in an enclosure or directly exposed to the elements, are grouped together and physically supported by mounting them to a structure, such as a tripod or tower.

| Height | Consider the height of the highest measurement level that a sensor must maintain and the corresponding necessary height of the mounting structure. |

| Stability | A tower is often secured to a user-supplied concrete pad on the ground. Typically, a tripod is secured directly to the ground; oftentimes, a guy wire kit is used to increase its stability. (If a tripod is located at a site with high wind, consider using duckbill anchors with the guy wire kit.) Consider using a guy wire kit to promote the stability of the following: tripods of all heights, towers that are 20 feet or taller, and towers that are subjected to severe winds and may suffer from wind-induced vibration. |

| Soil condition and terrain |

|

| Enclosure | Determine which environmental factors may negatively impact the measurements at your site, and select an appropriate enclosure that will minimize the effect(s) as much as possible. For example, if you are measuring air temperature and relative humidity with separate sensors, protect the sensors from direct sunlight and precipitation by placing them in a naturally or mechanically aspirated radiation shield. |

| Licensing | Investigate whether licenses are needed for the site location, such as for construction or a certified electrician. Depending on the height of the tower, a license may be needed to climb the tower. |

| Transportation | Consider not only where the automated weather station will be located, but also how the mounting equipment will be transported to the site. For example, if the mounting equipment needs to be transported in a pack up to a summit, review its weight and length specifications. As another example, if the mounting equipment needs to be transported via helicopter, review the equipment's dimensions to ensure that the equipment will fit within the confines of the helicopter's cabin. |

Campbell Scientific offers a wide variety of enclosure and mounting options.

Maintenance

As with any high-performance equipment, some level of maintenance (cleaning, calibration, and replacement) of the various automated weather station components is routinely required.

| Planning ahead | Review the recommended calibration and maintenance frequency of your station components so you can create a maintenance budget in terms of employee resources, travel time for site visits, and equipment costs. Determine which maintenance tasks can be handled onsite, such as with a field calibration tool, and which require equipment to be sent to the manufacturer. If downtime without data is not acceptable, have sufficient replacement parts (such as batteries) and backup equipment on hand. |

Campbell Scientific provides factory service, traceable calibrations, and replacement parts for many of its automated weather station components.

Additional Information

If you would like some background information regarding the concepts discussed in this section, review the Fundamentals section.